Access control system reader: development and manufacturing

- Project Overview

-

Commissioned by R.I.S.K. (Azerbaijan) we have developed the design and structure of enclosure for an access control system reader (ACS) and then put the finished product into small-scale production. Our customer have received a shipment of 400 readers compatible with HID R 10 (I class) to be used in the building of the State Oil Fund of the Republic of Azerbaijan (SOFAZ).

Key characteristics of the enclosure designed for ACS readers

- Simple and laconic style; the enclosure has no visible mounts

- Our customer’s logo was used as a status indicator

- Three modes were implemented: standby, access granted / denied

- Low production costs due to simple and thought out design of the enclosure: a base pad with PCBs and mounts + a double-layered front pad

- Three types of plastic were used: the first layer of 0.5 mm plastic with high quality polish + the second layer of plastic was coloured in the mass and covered with a black UV paint + the third layer of technological plastic for internal mounting

Project results In the process of project implementation, Promwad’s experts completed the following tasks:

— Selection of materials for the device enclosure

— Design and structure development

— Prototyping

— Production support: manufacturing of the initial batch (400 pcs.) - How It's Made

-

Customer

R.I.S.K. (Azerbaijan). The project is designed for the building of the State Oil Fund of the Republic of Azerbaijan (SOFAZ), which is under construction.

Objective

Development of the design and structure of an access control system reader compatible with HID R 10 (I class). Small-scale production and delivery of a batch of 400 finished devices to the customer.

Solution

1. Hardware

To ensure full HID compatibility, the reader uses 150 OEM, a specialized module manufactured by HID Global.

2. Enclosure design

The design of the reader is based on the basic requirements, such as a strict and stylish look and no visible fixtures.

The customer suggested the device should be given the shape of a glossy black rectangle, which was a solution guided by current trends in the design of mobile electronic devices.

The company logo was used as a status indicator (room access granted / denied).

- Standby mode – gold (original color of the customer's logo)

- Access granted – green

- Access denied – red

3. Enclosure structure and materials

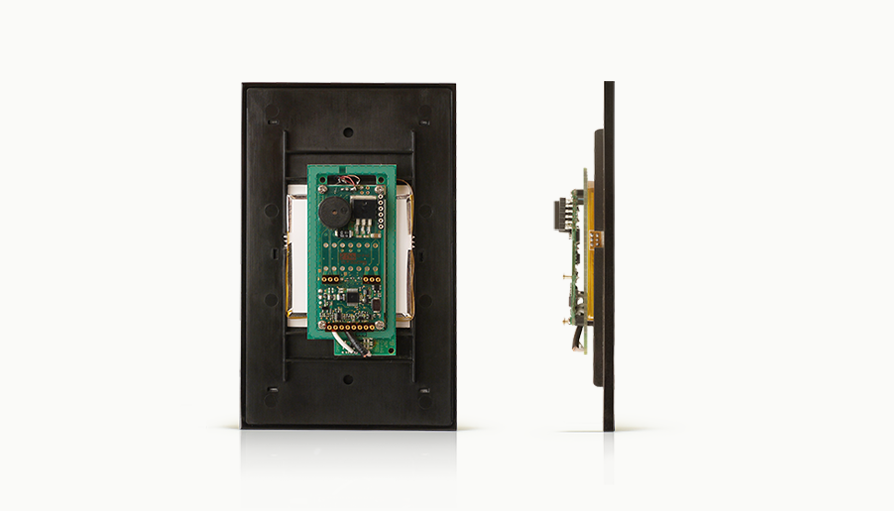

Structurally, the enclosure consists of the following components:

- A base pad on which printed circuit boards (PCBs) and all fasteners (to the wall) are installed

- A double-layered front pad equipped with latches that provide a secure hold on the base and allow the pad to be disconnected for mounting or fixing

The customer offered the following options for materials used in manufacturing the reader enclosure: ceramic one with transparent polycarbonate inserts, or plastic one. Promwad’s specialists selected plastic, taking into account an analysis of production technology capacity and price / quality estimates (high quality is difficult to obtain on flat ceramic large-surface parts; ceramics is also a relatively expensive material).

Three layers of plastic were used in manufacturing the enclosure. The inner layer is a technology layer for wall mounting; the second one is intended to make the product black (the plastic was coloured in the mass and additionally covered with a black UV paint to give it more glossy sheen). A transparent light guide in the form of the customer’s logo winds through these two layers. The third layer of plastic, 0.5 mm thick, with a high-quality polish, is the outer cover of the device, which gives it a mirror effect and a monolithic feel.

4. Start of Production

The first stage of production involved the manufacturing of the product’s test samples to test it for assemblability, operability, visual evaluation of the exterior and quality features of the enclosure. Necessary changes were made during four iterations, based on an analysis of test samples. These changes also included a provision for uniform luminosity of the logo indicator. Ultimately, the reader was launched into small-scale production (a batch of 400 pieces). The status display of the finished device was configured according to customer’s requirements.

Promwad’s trusted partner in China was selected as a production site, which was able to implement the project based on the specified quality parameters, timing and production cost.

If necessary, Promwad experts are ready to manufacture an additional small batch of devices for the customer.

Advantages

- Reasonable production cost of readers (at the level of regular items by HID Global Сorp.)

- The design of devices is based on the customer’s requirements

- The configuration of light and sound indication of readers can be changed using configuration process cards. Different readers can be configured in different display modes